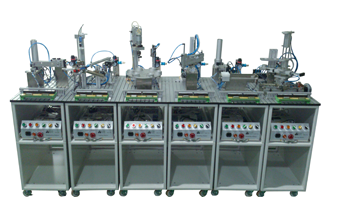

Modular Production Mechatronics Training System, Model No.: MPS-1700

Features:

MPS-1700 is a modular production mechatronics training system including distributing, testing, processing, handling, assembling, and storing stations.

This modular production system is designed based on a simulation of real industrial production processes.

Each station can be operated separately or 6 stations can be set up as a system to simulate a production line.

This system provides a total solution to teach students mechatronics design and control.

The learning concepts include sensors, PLC programming, motor control, pneumatic control, sequential control, installation, industrial wiring, industrial safety, trouble shooting, and automation.

This modular industry-based training system is flexible for future expansion.

1. Distributing Station: MPS-1701

Modules and components:

(a). Aluminum extruded profile Platform/ steel frame trolley

(b). PLC controller

(c). Feeding module

(d). Rotary arm module

(e). Pneumatic module: air treatment unit and valve unit

(f). Electrical control panel

(g). PLC I/O circuit wiring modules

Training contents:

(a). Station set-up

(b). Installation of tubing for pneumatic components

(c). Pneumatic linear and rotary drives

(d). Application of limit switch

(e). Pneumatic control circuits

(f). Programming and application of a PLC

(g). Rotary cylinder's speed and position adjustments

(h). Feeding mechanism

(i). Vacuum technology

(j). PLC sequential Control

(k). Wiring of electronic components

2. Testing Station: MPS-1702

Modules and Components:

(a). Aluminum extruded profile platform/ steel frame trolley

(b). PLC controller

(c). Material sorting module

(d). Height testing module

(e). Material handling module

(f). Pneumatic module: air treatment unit and valve unit

(g). Electrical control panel

(h). PLC I/O circuit wiring modules

Training contents:

(a). Station set-up

(b). Installation tubing for pneumatic components

(c). Material sorting

(d). Height measuring

(e). Color detecting

(f). Linear potentiometer property

(g). PLC A/D converter module

(h). Pneumatic control circuits

(i). Programming and application of a PLC

(j). Mechanism design

(k). Vacuum technology

(l). PLC sequential control

(m). Wiring of electronic components

3.Processing Station: MPS-1703

Modules and components:

(a). Aluminum extruded profile Platform/ steel frame trolley

(b). PLC controller

(c). Index table module is driven by worm gear mechanism with 6 puck holders

(d). Drill module

(e). Inspection module

(f). Pneumatic module: air treatment unit and valve unit

(g). Electrical control panel

(h). PLC I/O circuit wiring modules

Training contents:

(a). Station set-up

(b). Installation tubing for pneumatic components

(c). Rotary index table positioning

(d). DC motor control

(e). Drilling control

(f). Drill hole inspection

(g). Cylinder speed and position control

(h). Pneumatic control circuits

(i). Programming and application of a PLC

(j). Mechanism design

(k). Vacuum technology

(l). PLC sequential control

(m). Wiring of electronic components

4. Handling Station: MPS-1704

Modules and components:

(a). Aluminum extruded profile Platform/ steel frame trolley

(b). PLC controller

(c). 3-axis robotic arm module

(d). Pneumatic module: air treatment unit and valve unit

(e). Electrical control panel

(f). PLC I/O circuit wiring modules

Training contents:

(a). Station set-up

(b). Installation tubing for pneumatic components

(c). Sensor applications

(d). Robotic arm's speed and position control

(e). Pneumatic control circuits

(f). Programming and application of a PLC

(g). Mechanism design

(h). Vacuum technology

(i). PLC sequential control

(j). Wiring of electronic components

5. Assembly Station: MPS-1705

Modules and components:

(a). Aluminum extruded profile Platform/ steel frame trolley

(b). PLC controller

(c). Transfer module

(d). Feeding module

(e). Press module

(f). Pneumatic module: air treatment unit and valve unit

(g). Electrical control panel

(h). PLC I/O circuit wiring modules

Training contents:

(a). Station set-up

(b). Installation tubing for pneumatic components

(c). Sensor applications

(d). Cylinder's speed and position control

(e). Press machine simulation

(f). Feeding control

(g). Pneumatic control circuits

(h). Programming and application of a PLC

(i). Mechanism design

(j). Vacuum technology

(k). PLC sequential control

(l). Wiring of electronic component

Storing Station

6. Storing Station: MPS-1706

Modules and components:

(a). Aluminum extruded profile Platform/ steel frame trolley

(b). PLC controller

(c). 4-axis robotic arm mechanism

(d). Storage module

(e). Pneumatic module: air treatment unit and valve unit

(f). Electrical control panel

(g). PLC I/O circuit wiring modules

Training contents:

(a). Station set-up

(b). Installation tubing for pneumatic components

(c). Sensor applications

(d). Electrical drives

(e). Pneumatic control circuits

(f). Robotic arm's speed and position control

(g). Programming and application of a PLC

(h). Mechanism design

(i). Vacuum technology

(j). PLC sequential control

(k). Wiring of electronic components