Modular CD Production Mechatronics Trainer, Model Number: MCD-1600

Features:

* Innovation:

The first mechatronics control training system utilizes a mini compact disk production line for classroom training in the world.

* Hands-on Industrial Practice:

Experience learned from this system can be applied to industrial practice without any training gap learned vs. practical because most of the mechanisms in this system are custom made to fit various applications that students will encounter while working in the industrial.

* Training Efficiency:

This System provides students truly integrated learning. Students will be learning mechanics, electronics, pneumatics, sensors, troubleshooting, wiring of electronic components, and PLC controls.

After students are trained by this comprehensive learning system, they will find out the training system they school invests is more sophisticated than traditional automation systems. They can be providing their expertise to their employers seamlessly after they get a job in the industrial business.

1. Distributing Station: MCD-1601

Modules and Components:

(a). Aluminum extruded profile platform with steel frame trolley

(b). Mitsubishi or Allen Bradley PLC

(c). Robotic arm module

(d). CD Storage elevator module

(e). Pneumatic module: air service unit and solenoid valve unit

(f). Electrical control panel

(g). PLC I/O circuit wiring modules

Training Contents:

(a). Station set-up

(b). Installation of tubing for pneumatic components

(c). Application of reed switch

(d). Application of geared DC motor

(e). Application of fiber optic sensor

(f). Application of proximity switch

(g). Pneumatic linear and rotary drives

(h). Pneumatic control circuits

(i). Elevator mechanism

(j). Vacuum technology

(k). PLC sequential control

(l). Wiring of electronic components

2. Cooling Station: MCD-1602

Modules and Components:

(a). Aluminum extruded profile platform with steel frame trolley

(b). Mitsubishi or Allen Bradley PLC

(c). Cooling fan

(d). Geneva mechanism

(e). CD delivery mechanism

(f). Pneumatic module: air service unit and solenoid valve unit

(g). Electrical control panel

(h). PLC I/O circuit wiring modules

Training Contents:

(a). Station set-up

(b). Installation of tubing for pneumatic components

(c). Application of reed switch

(d). Application of Geneva mechanism

(e). Application of fiber optic sensor

(f). Application of signal amplifier

(g). Pneumatic control circuits

(h). Cooling fan module

(i). Vacuum technology

(j). PLC sequential control

(k). Wiring of electronic components

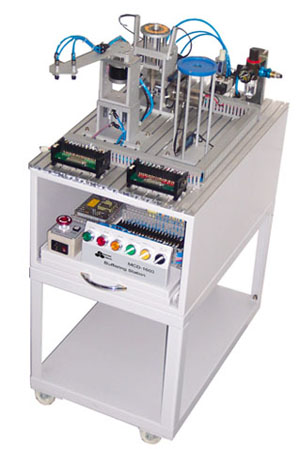

3. Buffering Station: MCD-1603

Modules and Components:

(a). Aluminum extruded profile platform with steel frame trolley

(b). Mitsubishi or Allen Bradley PLC

(c). CD Pick-up arm

(d). CD Buffering elevator

(e). CD Buffering stand

(f). Pneumatic module: air service unit and solenoid valve unit

(g). Electrical control panel

(h). PLC I/O circuit wiring modules

Training Contents:

(a). Station set-up

(b). Installation of tubing for pneumatic components

(c). Application of geared DC motor

(d). Application of proximity switch

(e). Application of fiber optic sensor

(f). Application of signal amplifier

(g). Application of reed switch

(h). Application of stepper motor

(i). Pneumatic control circuits

(j). Vacuum technology

(k). PLC sequential control

(l). Wiring of electronic components

4. Printing/ Baking Station: MCD-1604

Modules and Components:

(a). Aluminum extruded profile platform with steel frame trolley

(b). Mitsubishi or Allen Bradley PLC

(c). 3-arm CD transportation module

(d). CD Printing module

(e). CD Baking module

(f). CD Transfer stand

(g). Pneumatic module: air service unit and solenoid valve unit

(h). Electrical control panel

(i). PLC I/O circuit wiring modules

Training Contents:

(a). Station set-up

(b). Installation of tubing for pneumatic components

(c). Application of multiple cylinders' positioning control

(d). Application of temperature probe

(e). Application of heater

(f). Application of photo-electric switch

(g). Pneumatic control circuits

(h). Vacuum technology

(i). PLC sequential control

(j). Wiring of electronic components

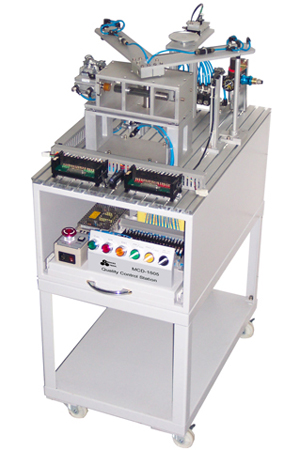

5. Quality Control Station: MCD-1605 Modules and Components:

Modules and Components:

(a). Aluminum extruded profile platform with steel frame trolley

(b). Mitsubishi or Allen Bradley PLC

(c). V-shaped CD distribution arm module

(d). CD Detection module

(e). Defective CD collection module

(f). Pneumatic module: air service unit and solenoid valve unit

(g). Electrical control panel

(h). PLC I/O circuit wiring modules

Training Contents:

(a). Station set-up

(b). Installation of tubing for pneumatic components

(c). Application of multiple cylinders' positioning control

(d). Application of dual rod cylinder

(e). Application of photo-electric switch

(f). Pneumatic control circuits

(g). Vacuum technology

(h). PLC sequential control

(i). Wiring of electronic components

6. Adhesive Coating Station: MCD-1606

Modules and Components:

(a). Aluminum extruded profile platform with steel frame trolley

(b). Mitsubishi or Allen Bradley PLC

(c). Circular rotation platform

(d). Rotary robotic arm module

(e). Adhesive coating module

(f). Pneumatic module: air service unit and solenoid valve unit

(g). Electrical control panel

(h). PLC I/O circuit wiring modules

Training Contents:

(a). Station set-up

(b). Installation of tubing for pneumatic components

(c). Application of proximity switch

(d). Application of induction motor

(e). Application of rotary cylinder

(f). Pneumatic control circuits

(g). Vacuum technology

(h). PLC sequential control

(i). Wiring of electronic components

7. UV Processing Station: MCD-1607

Modules and Components:

(a). Aluminum extruded profile platform with steel frame trolley

(b). Mitsubishi or Allen Bradley PLC

(c). UV processing module

(d). CD Transportation module

(e). Pneumatic module: air service unit and solenoid valve unit

(f). Electrical control panel

(g). PLC I/O circuit wiring modules

Training Contents:

(a). Station set-up

(b). Installation of tubing for pneumatic components

(c). Application of compact cylinders

(d). Application of limit switches

(e). Application of dual-rod cylinder

(f). Pneumatic control circuits

(g). Vacuum technology

(h). PLC sequential control

(i). Wiring of electronic components

8. Storing Station: MCD-1608

Modules and Components: (a). Aluminum extruded profile platform with steel frame trolley

(a). Aluminum extruded profile platform with steel frame trolley

(b). Mitsubishi or Allen Bradley PLC

(c). CD Delivery arm module

(d). CD Storing module

(e). Pneumatic module: air service unit and solenoid valve unit

(f). Electrical control panel

(g). PLC I/O circuit wiring modules

Training Contents:

(a). Station set-up

(b). Installation of tubing for pneumatic components

(c). Application of rotary cylinder

(d). Application of geared DC motor

(e). Application of photo-electric switch

(f). Pneumatic control circuits

(g). Vacuum technology

(h). PLC sequential control

(i). Wiring of electronic components