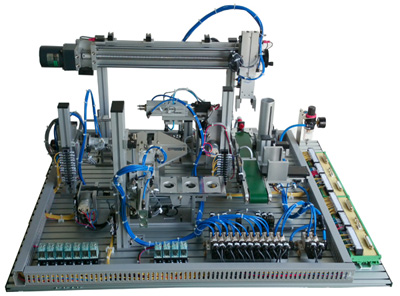

Flexible Mechatronics Trainer, Model No.: FMS-1500

Feature:

Flexible Mechatronics System, FMS-1500 is an all-in-one mechatronics training system. It provides freedom for the students to build a mechatronics system from the provided mechanisms. Students have the opportunity to learn how solenoid valves and relays work. They have to wire those devices by themselves and write a PLC program to control the system they design.

The manual covers 5 basic system configurations, which are shape detection, circular object orientation, rectangular object orientation, manufacturing, and weight detection. The beauty of this system is that it provides absolute flexibility for the users to gain true hands-on experience in an automation system.

Specifications:

A. Shape Detection Unit:

1.Gantry-type distribution Mechanism Module (FMS-1501-1)

Linear screw rod movement module,powered by an AC motor, traveling distance:13.5”

Position Sensor x 3, Limit sensor x 2

Dual-rod guided vertical cylinder Ø16×100ST

Ø20 Pneumatic gripper

Module base with adjustable slots for the module position adjustment.

Motor protection coupler prevents motor burnout. The coupler will release the screw rod while it is stuck externally due to program error.

2.Conveyor Belt Mechanism Module (FMS-1501-2)

Powered by DC gear motor 38RPM,belt travels 12.25” with tension adjustment.

Capacitive Proximity switch × 1,Fiber Optic Sensor with amplifier × 1

Module base with adjustable slots for the module position adjustment.

3.Circular Workpiece Slide and Rectangular Workpiece Platform (FMS-1501-3)

Ramp’s inner width is 1 5/8” with an adjustable ramp slope.

Both module bases come with adjustable slots for the module position adjustment.

4.Solenoid Valve Set and Air Treatment (FMS-1501-4)

Air Treatment with a sliding ON/OFF valve and a pressure regulator (0 ~ 160 psi).

24V Solenoid valves: Double, 2-position valve x 1, Single, 2-position valve x 1

B. Circular Object Orientation Unit:

5.Vertical Rotary Arm with suction nozzle (FMS-1502-1)

Adjustable rotary cylinder Ø20×180º, Timing belt guiding the suction nozzle always facing down, airflow regulator x 2, reed switch x 2, a suction unit with a pressure switch (works as a vacuum verifier).

The module base comes with adjustable slots for the module position adjustment.

6.Rotary Gripper with Vertical Elevator (FMS-1502-2)

Pneumatic cylinder for vertical movement Ø16×50ST

24V DC geared motor to rotate the grippers (to flip the circular workpiece).

Motor protection coupler prevents motor burnout. The coupler will release the gripper section while it is stuck externally due to program error.

Reed switch x 2 acts as rotary grippers’ rotation limits.

The module base comes with adjustable slots for the module position adjustment.

7.Circular Workpiece Color Detecting Station and Workpiece Slide (FMS-1502-3)

Circular workpiece color detecting platform, color sensor (Fiber Optic Sensor), object orientation sensor (Inductive Proximity Sensor), workpiece detection sensor (Reflective Photo-electric sensor)

Workpiece slide, a ring with inner diameter 1 9/16”

Both module bases come with adjustable slots for the module position adjustment.

8. Solenoid Valve set and Air Treatment (FMS-1502-4)

Air Treatment with a sliding ON/OFF valve and a pressure regulator (0 ~ 160 psi).

24V Solenoid valves: Doubletwo position valve x 3, Single, 2-position valve x 1

C. Rectangular Object Orientation Unit:

9.Rectangular Workpiece Rotation Module (FMS-1503-1)

The Elevator unit is powered by DC 24V motor to drive a CAM mechanism. It is equipped with two limit switches.

The rotary unit has 4 suction nozzles to hold the object and it can turn the object 90゚ or -90゚. It is equipped with 3 reed switches.

The module base comes with adjustable slots for the module position adjustment.

10.Rectangular Workpiece Feeding Module (FMS-1503-2)

It can accommodate up to 4 rectangular workpieces.

It is equipped with a reflective photo-microsensor for object orientation detection.

Workpiece slider Ø16×100ST is equipped with two reed switches.

The module base comes with adjustable slots for the module position adjustment.

11. Rectangular Workpiece Ramp (FMS-1503-3)

Slide with inner width 2 1/8”

Height and slope are adjustable.

The module base comes with adjustable slots for the module position adjustment.

12. Solenoid Valve Set and Air Treatment (FMS-1503-4)

Air Treatment with a sliding ON/OFF valve and a pressure regulator (0 ~ 160 psi).

24V Solenoid valves: Double, 2-position valve x 1, Single, 2-position valve x 3

D. Manufacturing Unit:

13.Indexing Table Module (FMS-1504-1)

Disc diameter 10”, precision CAM divider. Adjustable disc height.

DC 24V motor with speed reducer (20RPM), Positioning sensor x 1

Material sensor x1, workpiece detection sensor x1

The module base comes with adjustable slots for the module position adjustment.

14.Pneumatic Press Mold Module (FSM-1504-2)

Dual rod elevator cylinder, 1.5”x1.5” press area, reed switch x 2

The module base comes with adjustable slots for the module position adjustment.

15.Drill Module (FMS-1504-3)

Elevator cylinder Ø20×50ST with two guided check valves.

Drill powered by a DC 24V motor, 200 RPM.

The module base comes with adjustable slots for the module position adjustment.

16.Indexing Table Workpiece Detection Module (FMS-1504-4)

Workpiece detection sensor (optical reflective sensor).

The module base comes with an adjustable slot for the module position adjustment.

17. Solenoid Valve set and Air Treatment (FMS-1504-5)

Air Treatment with a sliding ON/OFF valve and a pressure regulator (0 ~ 160 psi).

24V Solenoid valves: Double, 2-position valve x 1, Single, 2-position valve x 1, 3-position Exhaust Center Valve x 1

E. Weight Selection Unit:

18. Weight selection module (FMS-1505-1)

Plastic loading plate with a spring return. The loading plate has a circular and rectangular concave slot on the top. A fiber optic sensor is installed at the edge of the loading plate.

Two photo interrupt sensors are used to detect the deflection of the load plate to decide the work piece's weight.

The module base comes with adjustable slots for the module position adjustment.

19.X-axis and Z-axis Robotic Arm Module (FMS-1505-2)

Vertical cylinder Ø16×75 mm with two guided rods.

Horizontal cylinder Ø20×150mm with two reed switches, and two speed regulators.

Grippers are powered by a Ø20 double acting cylinder. They can handle both circular and rectangular workpieces.

The module base comes with adjustable slots for the module position adjustment.

20.Mobile Storage Rack Module (FMS-1505-3)

The storage rack is driven by a DC geared motor.

Two critical limit switches for over-travel protection.

Three photo-interrupt sensors for positioning control.

Module base comes with adjustable slots for the module position adjustment.

Motor protection coupler prevents motor burnout. The coupler will release the screw rod while it is stuck externally due to program error.

21. Solenoid Valve set and Air Treatment (FMS-1505-4)

Air Treatment with a sliding ON/OFF valve and a pressure regulator (0 ~ 160 psi).

24V Solenoid valves: Double, 2-position valve x 2, Single, 2-position valve x 2

F. Experiment Platform and PLC Control Unit:

22.Foldable Aluminum Platform (FMS-1506)

Aluminum platform with T-slot 11 ¾” apart.

Fully extended dimensions 40” x 27.5”

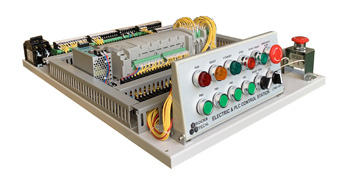

23. Control Panel & PLC Unit (FMS-1507)

Coated steel base (27.5” x 39.25”)

Fuseless power switch, DC Power Supply, PLC I/O terminals

PLC Controller

Coated Tilt Steel Control Panel (27.5” x 19.65”)

Red/Yellow/Green lights, 2-state selector switch x 1, 3-state selector switch x 1, Momentary Push-button x 4, Emergency Stop switch x 1, Green-lighted push-button switch x 1, Red-lighted push-button switch x 1

24. Power and Signal Connection Module (FMS-1508)