Object Orientation & Flipping Station, Model No.: OOF-1402

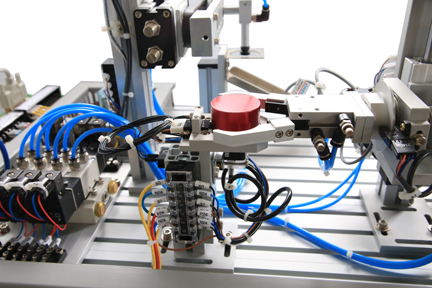

Circular Object Orientation and Flipping Station, OOF-1402 is a member of the Flexible mechatronics family. The main mechanisms in this system are the circular part's color and objection orientation detection module, the object flipping module, the rotary arm module.

This training system provides the users with a great hands-on practice opportunity to wire the modules to the PLC. There is a wire connection terminal on each module which makes it easier for different users to re-use the module without breaking it.

Interposing Relays are used for the PLC to control the DC geared motor. Students have to understand how a relay works in order to connect the wires correctly.

Solenoid valves are used for the PLC to control the pneumatic units. Students have to understand the structure of the solenoid vales and how they work so they can connect those tubes correctly to make the pneumatic units work as they are supposed to.

Specifications:

1. Circular part's color and object orientation detection module with adjustable slots in the X and Y directions.

2. Circular part's flipping gripper module with the motor protection device and adjustable slots in the X and Y directions.

3.Rotary arm module with a suction nozzle, timing belt, and adjustable slots in the X and Y directions.

4. Circular part's output ramp with adjustable slots in X, Y, and Z directions.

5. Run, Reset, Standby indicator lights

6. Start, Stop, EMS switches

7. Push-button x 4

8. Two-position selection switch x 1

9. Three-position selection switch x 1

10. Relay x 2

11. Air Treatment x 1

12. Single solenoid valve with spring return x 1

13. Double, 2-position solenoid valve x 3

14. Aluminum platform 18" x 28"

14. Allen Bradley Micro 850 PLC Controller